Equipment

tech-enabled business model

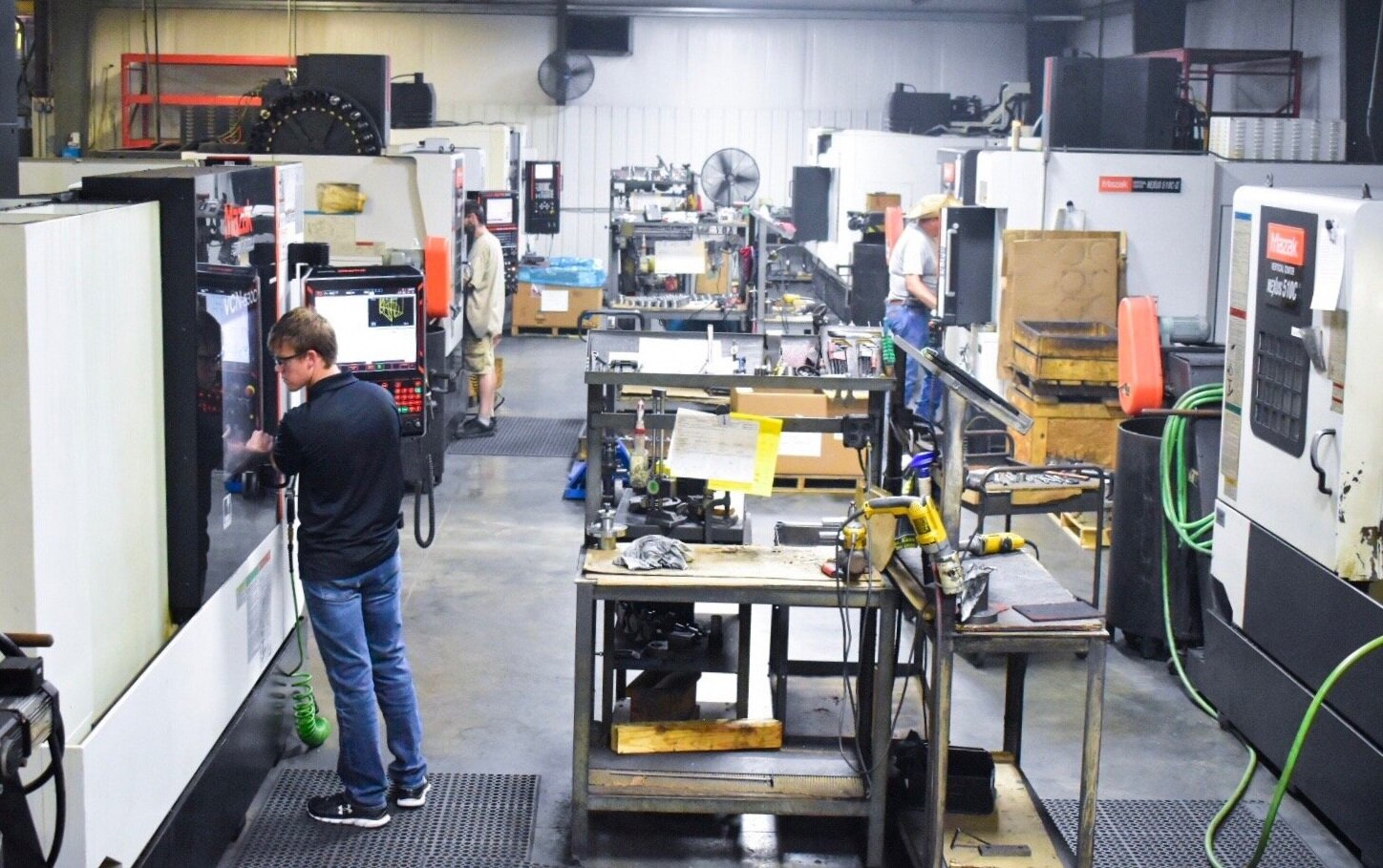

While the Manufacturing industry is continually incorporating new technological advancements, we too continue to incorporate our industry experience with new machining advancements through the use of state-of-the-art equipment and cutting-edge software. In doing this, VBMW works to eliminate machine set-up time and lengthy program runs, allowing for faster production times and a more satisfied customer. With the help of our climate controlled facility and thorough in-process quality checks we are able to maintain tight tolerances, and distinguish ourselves ahead of our competitors.

Application Software

AutoCAD

SolidWorks

MasterCam

SolutionWare CAD-CAM

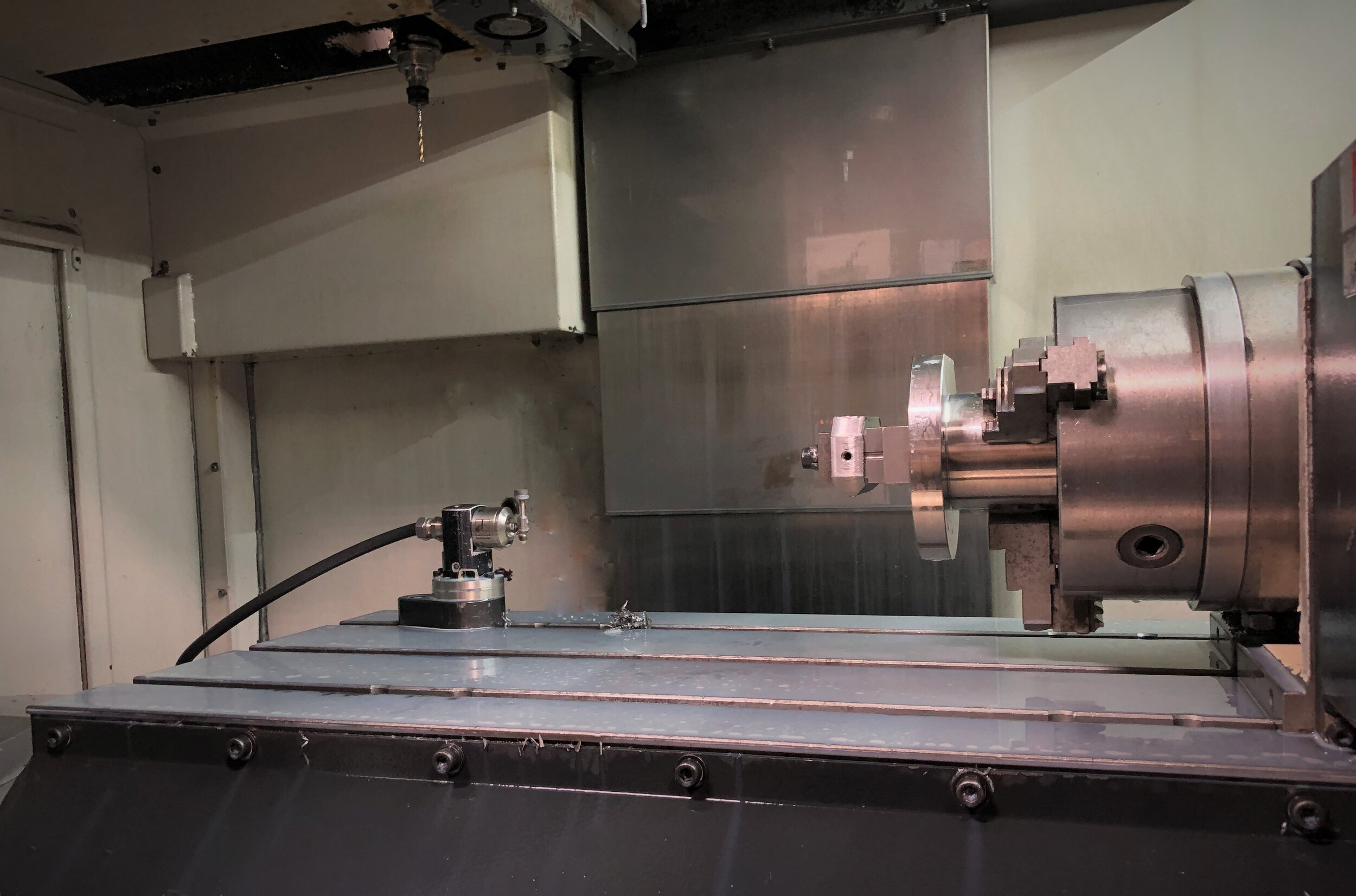

Horizontal Machining Centers

Van Becelaere Machine Works currently houses thirteen (13) Toyoda CNC horizontal machining centers, each with dual pallets ranging in sizes of 450mm (17.716in), 630mm (24.80in) and 800mm (31.496in). The machining travel capacity includes a 47”x40”x40” cube, with the largest machine having a 5500lb pallet load. Each of these machining centers has an automatic tool changer with tooling capacities ranging from 40 to 120 tools.

Vertical Machining Centers

Presently, VBMW has twelve (12) Mazak vertical machining centers in production. Eight (8) of the twelve (12) VMC’s are equipped with a 4th-axis rotary indexing system. The vertical machining centers all have the capacity to hold 24 tools, with the largest machine having a maximum travel of 65”x30”x26”.

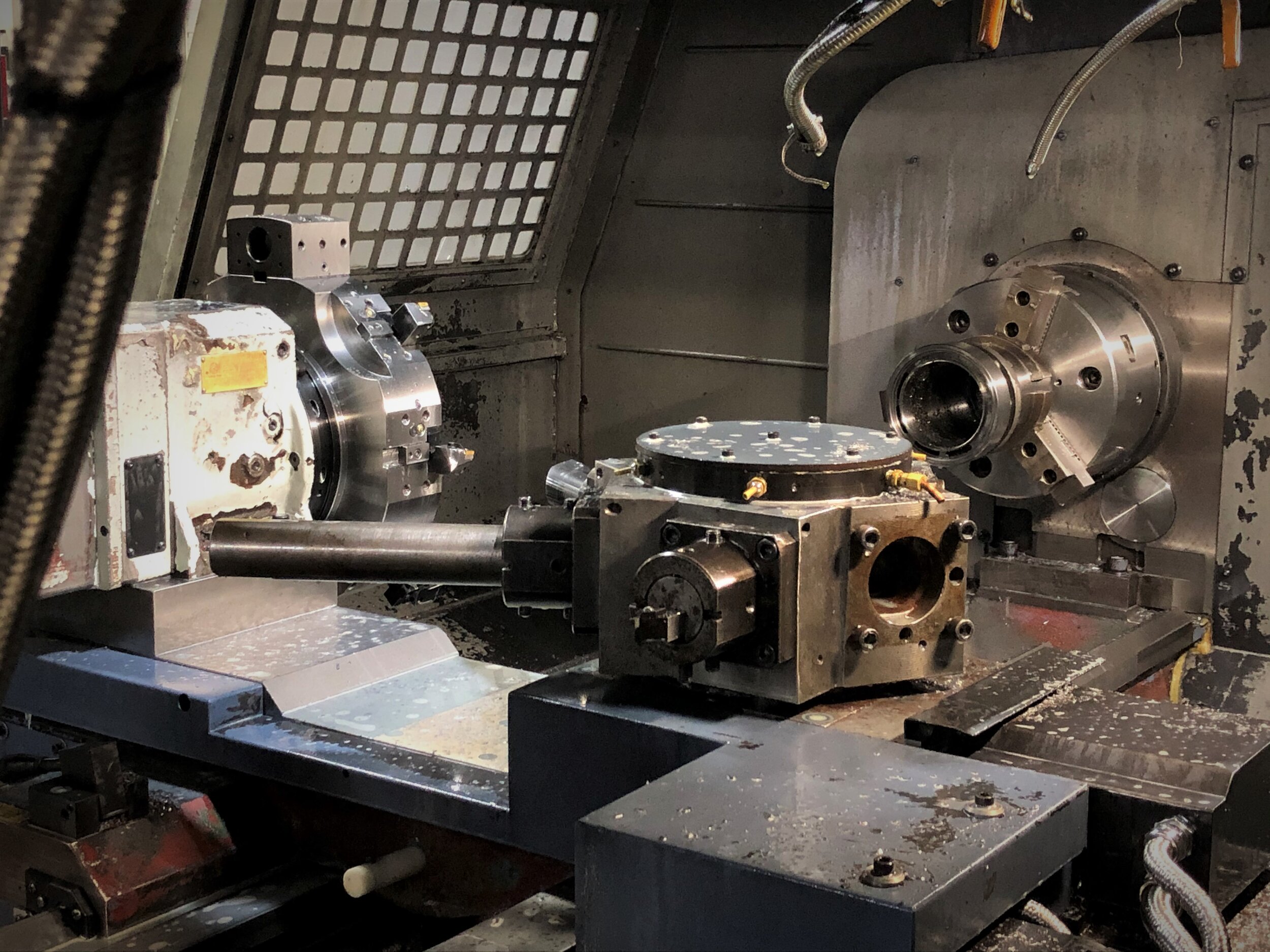

Turning Centers

VBMW currently maintains production on fourteen (14) CNC turning centers. The CNC turning centers range in size; the smallest having a 14” maximum turning diameter and a 14” maximum turning length, and the largest having a 24” maximum turning diameter and a 62” maximum turning length.

Grinders

VBMW’s grinding capabilities include a 16”x 32” surface grinder with automatic down-feed. A CNC cylindrical grinder is housed as well, features include Marposs O.D., lateral gauging, a grinding capacity of 7” in diameter, and a length of 18”.

Other Production Equipment

Honing capabilities are provided by a power stroke honing machine with a range of .062” I.D. to 5.250” I.D. and a length of 16”. Lapping capabilities are provided by a 32” free abrasive lapping machine. Balancing of parts is done using a dynamic vertical balancing machine.

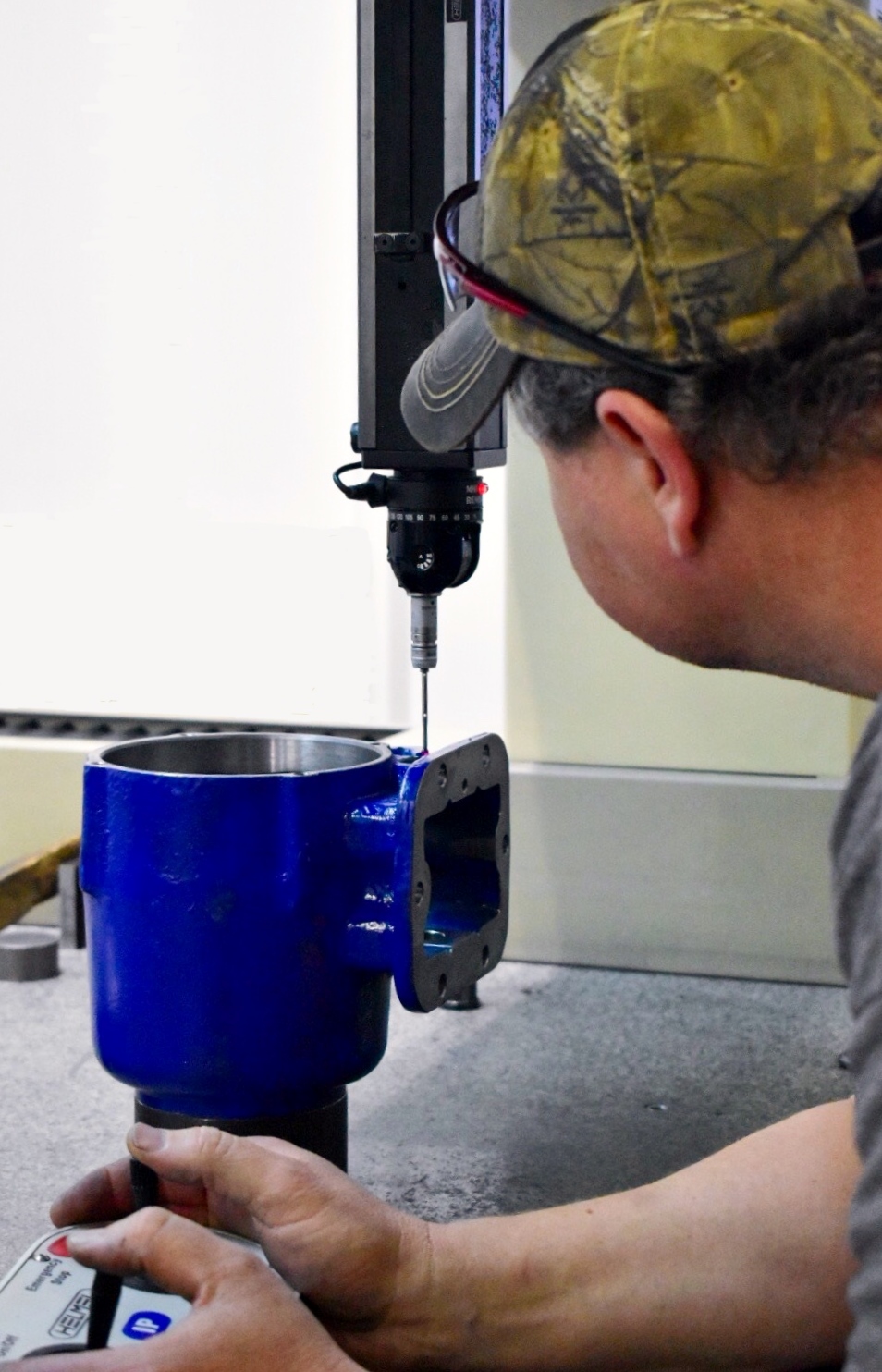

Quality Assurance

Van Becelaere Machine Works houses three coordinate measuring machines as our feature component in our continuous dedication to quality improvement. Our coordinate measuring machines along with capabilities such as; surface roughness testing and Rockwell hardness testing provide the proper means for full part inspection. From sample and first article inspection to reverse engineering this equipment ensures the manufacturing of a quality product.